On the development and market of "Current Colored Titanium"

|

From a lecture given by Takuji Horie, the President of Horie Corporation at the International Titanium Applications Conference & Exhibition. (San Francisco, Oct 8-11, 1997) |

| ||||||||

|

1) My concept of product developmental procedures for creating new titanium goods The way I formulate new titanium products may differ from many of your general product development procedures. When I begin developing new titanium products, or begin developing new technology to acquire such products, I never refer to reference manuals on titanium and what it's meant for. The reason why I never study existing documentation on titanium is because, I believe that if I do, my newly designed product will end up being quite similar to an existing product. The reason why I succeeded with my first encounter with titanium; I believe is simply because, I didn't have any knowledge of titanium to begin with. |

| ||||||||

|

11 years ago, a gentleman approached me with a sheet of titanium and asked if I would make him a gardening "planter" with the titanium he brought with him to my office. His original intension was to direct me as to how to go about and make this "planter". In spite of his request, I simply asked him to write down what he desired and to go back home, as developing products to the best extent was my job. To be honest, at the time I didn't know anything about Titanium. The following day, I completed his titanium planter and shipped it out to him. Later on, I was told that the gentleman in question spent 6 months trying to construct what I just accomplished. And hence forth, I started to recieve continuous orders for new development of titanium products from his company. And this was my first step into the titanium business. |

Titanium planer | ||||||||

|

My company's product development goal is to constantly come up with unique and original products. And to achieve this goal, my inspiration and the ideas produced by the other 12 members of my company are a very important part of this process. |

| ||||||||

|

|||||||||

| |||||||||

|

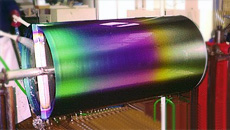

2) Our favorite technology and it's detail Among the many new titanium products I have developed. I have spent the most amount of time in developing the technology for coloring titanium through an anodic oxidation method. The surface of titanium is quite unpredictable and temperamental, hence it was quite difficult as the metal would not comply with our intentions. At times, I was able to achieve very clear colors, but when the process was repeated, I would be rewarded with smudges. I experienced quite a bit of difficulty at first, but I find that problems and issues we encounter also act as a instructor to our process. |

| ||||||||

|

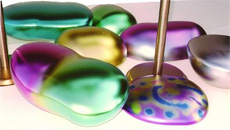

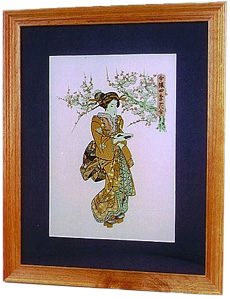

I developed my hypothesis from a small portion of my failures, and was able to confirm my hypothesis by various trials. I was able to master the technology of coloring titanium after about 3 years of constant improvement. And as you may be familiar, the color from titanium materializes by controlling the thickness of the titanium oxide (TiO2) film. The same principle as achieving the rainbow colors on a soap bubble. Over the past 10 years, my design room is now full with colored titanium products. It is now a world of powerful colors. Even with such bright colors, I find myself very at ease and calm in this sea of colors. I never get weary of the colors, as the colors produces from titanium are natural. I have also launched Titanium Art (pictures presented with colored titanium) in order to attractively present the wonders and produciblity of our titanium coloring technology. |

| ||||||||

|

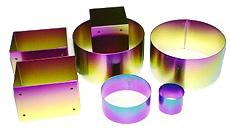

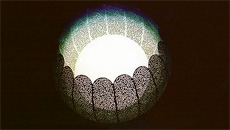

We are able to perfectly reproduce more than 10 titanium colors on a single sheet of titanium by numerous masking, and by adding our "gradation color technology." To the right, we have another piece from our Titanium Art series, "Tropical Fish." Not only is color used to design the fish, to present the peculiarities of the fish, scales have also been added with etching technology. And this etching technology has also progrossed with our development. Now it is possible to create various shaped holes, round or not and many delicate patterns; even on sheets of 1mm thickness of titanium. The use of etching technology has also become part of our daily operations. From an economical manufacturing cost point of view, sheets of titanium should be below 0.6mm. And of course, the etching machines we utilize has also been designed by ourselves. |

| ||||||||

|

Etching procedures are also much more advantageous than a punching die procedures, since with the etching process, one can manufacture even small number of products with small costs. A great way of proposing and designing various new products with limited costs. Also, with etched titanium sheets, one can develop and form various 3-dimensional commercial goods.

|

| ||||||||

Etched, colored and formed titanium |

|||||||||

| |||||||||

|

3) Introduction of new titanium products We also manufacture "press forming" products, such as our Outdoor series which include camping mugs, cookware, sierra cups, utencils, etc. For example, the following cooker was made from a sheet of titanium with a thickness of 0.4mm, and through a two-step press process, is drawn into a structure 95mm in diameter and 118mm in height. | |||||||||

|

|||||||||

| Other examples of our colored titanium and etching technology also include, signage, name plates, and other various "Titanium Art" as previously mentioned. | |||||||||

| |||||||||

|

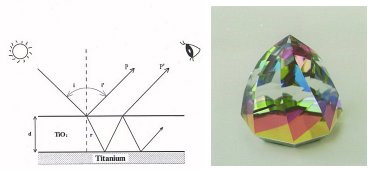

4) Stable reproduction and size limitations of coloring titanium | |||||||||

Mechanism of coloring titanium with current

| |||||||||

|

The mechanism of coloring is achieved by a process of anodized oxidation, and the color is selected from the light spectrum. For this reason, we can only produce colors within the series of colors from a rainbow. White (100% reflectin) or black (100% absorption) does not appear on our color chart. Please refer to our "Basic color list" from our company's handout document. These colors are all computer controlled and almost 100% repeatable. Not only can pure titanium be colored, but also other kinds of titanium alloys such as 6-4 Ti, β-C and Ti-X can be colored, and create their own color tone.

|

Basic color list from our Current Colored Titanium method. | ||||||||

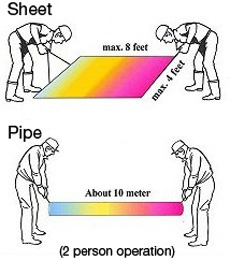

| The maximum size of colored titanium we can achieve is usually determined by the capability of what 2 people can handle. As titanium is naturally a light material, even a 10 meter length pipe can be controlled by 2 people. In cases of sheets of titanium, we are capable of coloring a titanium sheet up to 8' x 4' (1,200mm x 2,400mm) in size. | |||||||||

Maximum size we can color titanium |

| ||||||||

| In the case of constructing three-dimensional formed titanium objects, such as monuments. The size of the operating bath determines the maximum size of the colored material. When a very large titanium structure is to be colored, it must be devised into smaller parts and colored separately. The colors of each separate parts will obviously be accordingly matched. |

Three dimensional colored titanium objects | ||||||||

| And example of special coloring process. Fine titanium wire was colored continuously with the use the use of a bobbin. | |||||||||

Colored fine titanium wire | |||||||||

| |||||||||

|

5) HORIE's sales promotion methods Our company is very small, with only 13 staff members, including myself. We have no sales or marketing specialists, and plan to manufacture all products ourselves, also attending exhibits at Trade Fairs in Tokyo 2-3 times a year. We hope the attract clients directly with our unique ideas and further our relationship by moving encounters into sales. The difficulty from selling new titanium products for use is that we find that we must always explain why titanium is required or necessary for creating our products.

|  | ||||||||

|

| |||||||||

There's the proverb "Seeing is believing." And strongly hope that you will see the beauty of colored titanium. Once people actually lay their eyes on our colored titanium products, they then begin to see and understand how wonderful they really are. I am very proud to see that the participants of this conference are aware of the benefits and advantages of titanium. But reget that, generally speaking, many people still do not understand the benefits of titanium. I ask for you assistance, in spreading the word of the wonders of titanium. |

| ||||||||

| |||||||||

|

6) The mysterious powers of titanium Titanium has many advantages; strength, lightweight and being corrosion resistant. Titanium also has other mysterious advantages, and we at HORIE Corporation hope to utilize and apply some of these mysterious advantages into developing new products. Oxidized titanium film has a number of mysterious functions. For example, when we enjoy a beer or any form of beverage with colored titanium cups or mugs, we can feel and taste the finer aspects of the drink. If you question my claim, I certainly recommend you to aquire a colored titanium mug and try it out for yourself.

|

| ||||||||

|

At our design room at HORIE Co. in Japan, we have a fish tank that is full of colored titanium mesh balls, and an interesting thing occurs. With active bubbles in the fish tank, the mesh balls catches the air, floats up and then sink once the air is released at the surface. We have also found that when strong light is shone onto the colored titanium mesh balls, due to a photocatalytic water splitting effect, over time small oxygen bubbles form around the mesh balls and the mesh balls begin to move more actively. Moreover, we found that the water does not go bad for more than three years, due to disinfection of the water by titanium dioxide photocatalysis. We've added enough water to compensate the naturally vaporized amount, and yet the water remained clear. Photocatalysis effects of oxidized titanium is well known already, and I have observed and experienced this effect for 6 years. In soda water, the titanium balls swim around quite actively; floating, sinking and rotating as if alive. A wonderful mysterious movement. Over a long period of time, the movement subsides, but once dry and inserted back into the water, off it goes again. Such movement from light catalyzing effects only last as long as there's a membrane of oxidized titanium on the surface of the mesh balls.

|

| ||||||||

|

Have you ever held your hand over a piece of titanium? Some say that at a distance of 20~30cm, your hands might feel warmer. And some might be more sensitive to this than others. Some naive people might experience this effect, and as a result, I have created titanium bracelets for people who believe this mysterious effect. Some 80% of people who use titanium bracelets say that their stiff shoulders have been cured. In anycase, I always wear a titanium bracelet.

|

| ||||||||

|

Tsubame city is famous in Japan for manufacturing many kinds of metal tablewares. There are countless number of spoons made in the city of Tsubame, by only 6 companies, including my own manufacture titanium spoons. When I decided to make my dining table more colorful by developing colored titanium tableware, I found myself having a wonderful experience. I found the meals I was having to be more delicious when I was using titanium spoons. The reason behind this is because, titanium metals do not ionize, and we can genuinely enjoy our meal, and not be distracted by the taste of the utensils. When we use stainless steel spoons, our food is ionized by ferrous ions, and taste can be altered with such ions. Our taste buds have been paralyzed for many years; so let us take back and enjoy the original taste of the such delicious dishes with a titanium spoon! |

| ||||||||

| |||||||||

|

7) Future development agendas

| |||||||||

|

|||||||||

Our company is very small, hence our area activity is also very small. But I am confident that our passion for the development of titanium for more usuable products is not inferior to anybody else. I will leave the large scale chemical plant projects and development of aerocraft engineering projects to the big titanium companies. My goal is to continue developing titanium products for everyday use. I shall continue the adventure and challenge of getting titanium recognized enough to be present in everybody's daily life.

|

| ||||||||